The post Leveraging LiDAR Technology and Robotic Arms for Automated Warehouse Management appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>Automated Warehouse Management: Scanning and Mapping Warehouse Inventory

Efficient inventory management is crucial for the smooth operation of warehouses. Traditionally, this process has relied heavily on manual labor, which is time-consuming, error-prone, and costly. However, the advent of LiDAR technology and robotic arms offers a sophisticated solution to these challenges.

What is LiDAR?

LiDAR is a remote sensing method that uses laser light to measure distances and create detailed, three-dimensional maps of environments. This technology is known for its accuracy and ability to function in various lighting conditions, making it ideal for indoor applications like warehouses.

How LiDAR and Robotic Arms Work Together

When combined with robotic arms, LiDAR technology can transform warehouse operations. Here’s how:

- Scanning and Mapping: LiDAR-equipped robotic arms can scan and map the entire warehouse in real-time. This mapping creates a precise 3D model of the warehouse, detailing the location and dimensions of shelves, aisles, and inventory.

- Inventory Tracking: The 3D model allows for accurate tracking of inventory. Robotic arms can scan barcodes or RFID tags on items, updating the inventory system in real time. This reduces the chances of human error and ensures inventory records are always up to date.

- Efficient Space Utilization: The detailed maps generated by LiDAR help in optimizing space utilization. Robotic arms can place items in the most efficient locations, ensuring that space is maximized and items are easy to retrieve.

- Safety and Precision: Robotic arms equipped with LiDAR sensors can navigate the warehouse environment safely and precisely. They can detect obstacles and avoid collisions, ensuring smooth operations and reducing the risk of damage to goods and equipment.

Benefits of Implementing LiDAR and Robotic Arms in Warehouses

- Increased Efficiency: Automated systems can operate continuously without breaks, significantly increasing the efficiency of warehouse operations.

- Cost Savings: Reducing the reliance on manual labor can lead to substantial cost savings in the long run.

- Enhanced Accuracy: Automated scanning and mapping reduce the likelihood of errors, leading to more accurate inventory records.

- Improved Safety: Automation minimizes the risk of accidents associated with manual handling of goods.

Conclusion

The integration of LiDAR technology and robotic arms in warehouse management is a game-changer. It offers a high-tech solution to traditional inventory challenges, providing benefits that include increased efficiency, cost savings, and improved accuracy. As this technology continues to advance, we can expect to see even more innovative applications across various industries.

The post Leveraging LiDAR Technology and Robotic Arms for Automated Warehouse Management appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The post Smart Construction Scenarios Made Possible with LiDAR Technology appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>LiDAR?technology uses laser light to measure distances with high precision. By emitting laser pulses and measuring the time it takes for them to bounce back after hitting an object or surface, LiDAR?scanners can create detailed 3D maps of environments. This data can then be used for a variety of applications in smart construction scenarios.

Benefits of using LiDAR?technology in construction

One of the most significant benefits of using LiDAR technology in construction is its ability to provide accurate measurements quickly. Traditional surveying methods can be time-consuming and labor-intensive, requiring manual measurements and calculations. LiDAR scanners, on the other hand, can capture millions of data points in a matter of minutes, allowing for faster project planning and design.

Another advantage of using LiDAR technology in construction is its ability to create highly detailed 3D models of existing structures or landscapes. These models can be used for site analysis, clash detection, as-built documentation, progress monitoring, and more. By having a precise digital representation of a project site, construction teams can identify potential issues early on and make informed decisions to avoid costly mistakes down the line.

Smart construction scenarios made possible with LiDAR?technology include:

1. Site Analysis: Before breaking ground on a new project, it’s essential to conduct a thorough analysis of the site conditions. LiDAR scans can provide accurate topographic data that helps engineers understand terrain features such as slopes, elevation changes, and drainage patterns. This information is crucial for designing foundations that are stable and resilient against natural elements.

2. Clash Detection: In complex building projects where multiple systems need to coexist within limited spaces (such as HVAC ducts running through structural beams), clash detection is critical to prevent conflicts during construction or operation. By overlaying different design models onto each other using LiDAR data, teams can identify clashes early on and make necessary adjustments before they become costly issues.

3. Progress Monitoring: Keeping track of project progress is essential for meeting deadlines and budget constraints effectively. With regular LiDAR scans throughout different stages of construction, teams can compare actual progress against planned schedules, accurately assess work quality, and monitor material stockpiles to manage logistics efficiently.

4. As-Built Documentation: Once a project is completed; having accurate as-built documentation ensures future maintenance activities run smoothly without any surprises or delays. By comparing final constructed elements with initial designs using LiDAR scans, teams ensure everything has been built according to specifications.

5. Asset Management: Beyond just aiding during initial phases, LiDAR technology also plays a crucial role in managing assets post-construction phase. By creating digital-twin building infrastructure, facility managers gain insights into the performance condition of assets, enabling predictive maintenance strategies to optimize operations and reduce costs.

Tips for Efficiently Implementing Smart Construction Scenarios with LiDAR?Technology:

1. Understand Your Project Needs: Before investing in LiDAR?equipment services, it’s important to understand the specific requirements and goals of your projects. Identify areas where LiDAR?could add value, such as improving accuracy, reducing errors, and increasing efficiency.

2. Choose the Right Equipment: There are various types of LiDAR?scanners available on the market, each designed for specific applications. Choose equipment that suits your needs, whether it is a static or mobile airborne scanner. Ensure capabilities align with requirements and desired outcomes.

3. Train Your Team: While LiDAR?technology offers many benefits, it also comes with a learning curve. Ensure team members are properly trained on how to operate, maintain equipment, and interpret data effectively. Utilize training resources provided by manufacturers and vendors, and stay updated with the latest developments and best practices in the field.

4. Integrate Data Across Platforms: To fully leverage the benefits of LiDAR?technology, seamless integration across platforms and software is essential. Make sure the data captured by scanners is compatible with the CAD, BIM, and GIS software used by your organization. This allows easy sharing and collaboration among team members and stakeholders involved in the project.

5. Establish Quality Control Processes: To ensure the accuracy and reliability of collected data, establish quality control processes, verify results regularly, Conduct checks cross-referencing traditional survey methods, validate findings Identify and rectify any discrepancies early, and minimize errors in later stages.

6. Collaborate with Experts: If you’re new to implementing LiDAR?technology, seek guidance from experts in the field. Collaborating with experienced professional consultants helps navigate challenges and maximize the benefits offered by this advanced tool. Their insights and knowledge are invaluable, ensuring the successful implementation of smart construction scenarios.?

7. Maintain Regular Scanning Schedule: A consistent scanning schedule throughout different phases of your projects is critical for monitoring progress and detecting issues early. Avoid gaps between scans to ensure up-to-date information is available at all times. Adjust?the frequency?needed depending on the complexity and scope of your projects.?

8. Evaluate Return on Investment (ROI): While adopting new technologies like LiDAR is beneficial in the long run, it’s important to evaluate the return on investment upfront. Consider the costs associated with purchasing, maintaining equipment, and training staff, compared with the potential savings efficiencies gained from improved processes, and reduced rework errors. Make informed decisions based on comprehensive cost-benefit analysis.

In conclusion, LiDAR?Technology has transformed the way we approach plans, execute, and monitor construction projects. Its ability to provide accurate, detailed, real-time information enables smarter decision-making and improves overall efficiency and productivity on job sites. By understanding and implementing the best practices and tips mentioned above, organizations position themselves to successfully harness the full potential of this groundbreaking tool. Stay ahead of the competition and embrace future smart construction scenarios made possible by LiDAR?technology.

The post Smart Construction Scenarios Made Possible with LiDAR Technology appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The post How LiDAR?Transforms Large-Scale Pile Surveys appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>How LiDAR?Transforms Large-scale Pile Surveys?

1. Accurate Volume Calculations:

One of the key advantages of using LiDAR?for large-scale pile surveys is its ability to provide highly accurate volume calculations. Traditional methods of measuring piles?often?involve manual measurements or?using?GPS technology, which can be time-consuming and prone to errors.?With?LiDAR?technology,?3D point cloud data?is collected?by emitting laser pulses from a sensor mounted on an aircraft or ground-based vehicle.?This data is then processed using specialized software to create detailed 3D models of the piles, allowing for precise volume calculations with minimal human intervention.

2. Improved Safety:

Large-scale pile surveys can be hazardous due to the unstable nature of the materials being measured. Using traditional surveying methods often requires workers to physically climb on top of piles or use heavy machinery for measurements, putting them at risk of accidents or injuries. LiDAR eliminates the need for workers to enter potentially dangerous areas by capturing data remotely from a safe distance. This not only improves safety conditions but also reduces downtime associated with accidents on site.

3. Increased Efficiency:

LiDAR technology significantly increases efficiency in conducting large-scale pile surveys compared to traditional methods. The speed at which LiDAR sensors can collect data allows for quick turnaround times in generating accurate volume calculations and 3D models of piles. This efficiency translates into cost savings for companies as fewer resources are required for surveying activities, leading to improved project timelines and overall productivity.

4. Enhanced Data Visualization:

The 3D point cloud data generated by LiDAR technology provides detailed visualizations that offer valuable insights into the shape, size, and distribution of materials within piles. These visualizations enable stakeholders to make informed decisions regarding inventory management, resource allocation, and site planning based on real-time information about their stockpiles.

5. Monitoring Changes Over Time:

Another significant benefit of using LiDAR for large-scale pile surveys is its capability to monitor changes in pile volumes over time accurately. By comparing multiple scans taken at different intervals, companies can track material movement, erosion, or deposition within their stockpiles. This information helps optimize operational processes, identify potential issues early on, and ensure compliance with regulations regarding stockpile management.

6. Environmental Impact Assessment:

In industries such as mining where environmental impact assessments are crucial, LiDAR plays a vital role in monitoring changes in land use over time. By accurately measuring volumes of excavated materials, LiDAR helps companies assess their environmental footprint more effectively and implement sustainable practices.

7. Cost-Effective Solution:

While initial investment costs may be higher when implementing LiDAR technology for large-scale pile surveys, the long-term benefits outweigh the upfront expenses. The accuracy and efficiency provided by LiDAR technology result in reduced labor costs, fewer errors, and improved decision-making processes that ultimately lead to cost savings for companies.

Industries benefiting?from LiDAR?technology:

1. Construction Industry

One industry that greatly benefits from LiDAR technology in pile surveys is the construction industry. Construction companies often deal with large quantities of materials that need to be measured and monitored regularly. With LiDAR technology, these companies can quickly and accurately survey their stockpiles without the need for manual measurements or physical inspections. This not only saves time but also reduces the risk of human error in calculating volumes.

2. Mining Industry

In the mining industry, LiDAR technology is also transforming how pile surveys are conducted. Mining companies rely on accurate volume measurements to track their inventory levels and plan for future operations effectively. By using LiDAR scanners mounted on drones or ground-based vehicles, mining companies can survey their stockpiles more frequently and with higher precision than ever before. This real-time data allows them to make informed decisions quickly and optimize their operations for maximum efficiency.

3. Agriculture

Another industry where LiDAR technology is making a significant impact on pile surveys is agriculture. Farmers often store large quantities of grains or fertilizers in piles that need to be monitored regularly for inventory management purposes. With LiDAR scanners mounted on tractors or drones, farmers can quickly survey their stockpiles without disrupting their daily operations. This data helps them track inventory levels accurately and avoid costly shortages or overstock situations.

4. Forestry Industry

The forestry industry is also benefiting from the use of LiDAR technology in pile surveys. Forestry companies manage vast amounts of wood chips or logs that are stored in piles at various locations. By using LiDAR scanners mounted on helicopters or drones, these companies can efficiently measure the volume of their stockpiles without having to rely on manual measurements or estimates. This data enables them to optimize transportation logistics and ensure they have enough inventory to meet demand.

5. Environmental Monitoring

In addition to these industries, LiDAR technology is also being used in environmental monitoring applications such as landfills and disaster response scenarios where accurate volume measurements are crucial for decision-making processes.

Specific scenarios where LiDAR?transforms large-scale pile surveys include:

1) Inventory Management: Companies can use LiDAR?technology to monitor their stockpile levels more frequently and accurately than traditional methods allow. This real-time data helps them track inventory turnover rates, identify potential shortages or surpluses early on, and make informed decisions about restocking orders.

2) Safety Inspections: By conducting regular pile surveys with LiDAR?scanners, organizations can identify potential safety hazards?such?as unstable slopes or overloading conditions?before?they escalate into serious incidents. This proactive approach helps prevent accidents and ensures a safe working environment for employees.

3) Regulatory Compliance: Many industries are subject to regulations regarding storage capacity limits or environmental impact assessments related to material stockpiles. By using LiDAR?technology for pile surveys, organizations can demonstrate compliance with regulatory requirements by providing accurate volume measurements as needed.

4) Cost Savings: Traditional methods of conducting large-scale pile surveys involve?manual?labor-intensive processes that are time-consuming and prone to errors resulting in additional costs due to inaccuracies during measurement calculations; however, LiDAR?Technology streamlines this process by providing fast results with high accuracy?which?ultimately leads towards cost savings

Conclusion?

Overall, LiDAR Technology has transformed large-scale Pile Surveys across multiple industries by offering faster, safer, cost-effective, and highly accurate solutions compared to traditional methods. This advanced technology not only improves operational efficiency but also enables better decision-making processes based on real-time data insights. The future looks promising as more industries continue adopting this innovative solution for managing their material stockpiles with greater ease and precision.

The post How LiDAR?Transforms Large-Scale Pile Surveys appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The post Common Misconception About LiDAR appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>Common Misconception 1: LiDAR is the same as radar or sonar

One of the most common misconceptions about LiDAR is that it is the same as radar or sonar. While all three technologies use remote sensing to detect objects and their distances, they operate on different principles. Radar uses radio waves, while sonar uses sound waves to measure distances. On the other hand, LiDAR uses laser pulses to create detailed 3D maps of an area.

To correct this misconception, it’s important to understand that each technology has its strengths and limitations. Radar is better suited for long-range detection in adverse weather conditions, while sonar is ideal for underwater mapping. LiDAR excels in creating high-resolution maps with precise measurements of objects on the ground.

Common Misconception 2: LiDAR can only be used for mapping terrain

Another common misconception about LiDAR is that it can only be used for mapping terrain or creating topographic maps. While LiDAR is indeed widely used in cartography and geospatial applications, its versatility extends far beyond terrain mapping.

LiDAR technology can also be utilized for a wide range of applications such as urban planning, infrastructure monitoring, forestry management, archaeology, disaster response, and even autonomous driving systems. Its ability to generate highly accurate 3D models makes it an invaluable tool for various industries seeking precise spatial data.

To correct this misconception, it’s essential to highlight the diverse range of applications where LiDAR can be applied effectively. By showcasing real-world examples of how LiDAR technology is being used across different sectors, we can dispel the notion that its utility is limited to terrain mapping alone.

Common Misconception 3: LiDAR data collection requires expensive equipment

Some people believe that collecting LiDAR data requires expensive equipment and specialized training which makes it inaccessible for many users or organizations with limited budgets. While high-end professional-grade LiDAR systems do come with a hefty price tag due to their advanced features and capabilities, there are also more affordable options available on the market today such as lightweight portable scanners or drones equipped with integrated LiDAR sensors which offer cost-effective solutions without compromising on quality results.

By debunking this misconception through education about the range of options available at different price points, we can encourage wider adoption of LiDAR technology among users whose cost concerns may have previously been deterred.

Common Misconception 4: LiDAR cannot penetrate dense vegetation

Another common misconception about LiDAR technology is that it cannot penetrate dense vegetation effectively, resulting in incomplete or inaccurate data when scanning forested areas.

While it’s true that vegetation can obstruct LiDAR pulses from reaching the ground surface, modern multi-return systems are capable of capturing multiple reflections within a single pulse, allowing them to penetrate through tree canopy layers and generate detailed elevation models even in densely vegetated environments.

By addressing this misconception through awareness-building efforts around advancements in multi-return LiDAR systems, we can showcase how these technologies have overcome previous limitations and are now able to capture accurate elevation data beneath forest canopies.

Common Misconception 5: Processing LiDAR data requires advanced technical skills

Some individuals may believe that processing LiDAR data requires advanced technical skills and specialized software knowledge, making it inaccessible for those without a background in GIS or remote sensing.

While there are indeed complex algorithms involved in processing LiDAR datasets, there are also user-friendly software tools available today that streamline the process and make it more accessible even for beginners.

By providing training resources and tutorials on how to process LiDAR data using these tools, we can empower more users from diverse backgrounds to leverage LiDAR technology effectively without feeling intimidated by perceived technical barriers.

LiDAR Working Principle

LiDAR, which stands for Light Detection and Ranging, is a remote sensing technology that uses light in the form of a pulsed laser to measure variable distances to the Earth. This technology works by sending out laser pulses toward a target and measuring the time it takes for the light to bounce back. By calculating the time it takes for the light to return, LiDAR systems can create highly accurate 3D maps of objects and environments.

One of the key components of LiDAR technology is its ability to generate precise measurements with high resolution. This makes it an invaluable tool in various industries such as urban planning, forestry, archaeology, agriculture, and autonomous vehicles.

LiDAR Applications

Urban Planning

One of the key areas where LiDAR technology is making a significant impact is urban planning. By providing accurate and high-resolution data on buildings, roads, and other infrastructure, LiDAR helps city planners make informed decisions about land use, transportation systems, and environmental conservation. This data can also be used to simulate urban growth scenarios and optimize resource allocation for sustainable development.

Infrastructure Monitoring

In addition to urban planning, LiDAR technology plays a crucial role in infrastructure monitoring. By detecting changes in structures such as bridges, dams, and pipelines over time, engineers can identify potential risks early on and take preventive measures to ensure public safety. LiDAR data can also be used for asset management purposes by tracking the condition of infrastructure assets and scheduling maintenance activities accordingly.

Forestry Management

Forestry management is another area where LiDAR technology has proven to be invaluable. By scanning forests from above, LiDAR sensors can provide detailed information about tree height, density, species composition, and overall health. This data enables forest managers to make informed decisions about timber harvesting practices, wildlife habitat conservation efforts, fire risk assessment, and carbon sequestration initiatives.

Archaeology

Archaeologists are also leveraging the power of LiDAR technology to uncover hidden archaeological sites buried beneath dense vegetation or layers of soil. By conducting aerial surveys with LiDAR-equipped drones or aircraft, researchers can create highly accurate digital models of ancient landscapes that reveal previously unknown structures or artifacts. This non-invasive approach not only saves time but also helps preserve fragile archaeological sites for future generations.

Disaster Response

During natural disasters such as earthquakes, floods, or wildfires, rapid response teams rely on LiDar Technology for quick damage assessment. The high-resolution 3d maps generated by Lidar sensors help emergency responders identify areas that are most affected by the disaster, prioritize rescue operations, and plan evacuation routes efficiently.

Autonomous Driving Systems

Autonomous driving systems heavily depend on Lidar Technology. Self-driving cars use Lidar sensors mounted on their roofs to detect obstacles such as pedestrians, vehicles, and road signs in real time. These sensors provide precise distance measurements which enable autonomous vehicles to navigate safely through complex traffic scenarios without human intervention.

Overall, LiDAR technology has revolutionized how we collect data about our world with its high-precision measurement capabilities across various industries from urban planning to archaeology. As this technology continues to advance rapidly over time we can expect even more innovative applications that will further enhance our understanding of our environment while improving efficiency across different sectors.

Conclusion

LiDAR technology offers a powerful toolset for capturing highly accurate spatial data across various industries. By debunking common misconceptions surrounding LiDAR, we can help promote wider adoption of this transformative technology and unlock its full potential for solving complex challenges in fields ranging from urban planning to environmental conservation.

Through education, awareness-building efforts, and showcasing real-world examples, we can demystify LiDAR and highlight its versatility as a valuable asset for organizations seeking precise spatial information.

Let’s continue spreading awareness about LiDAR’s capabilities and dispelling myths surrounding this innovative technology. Together, let’s harness the power of LiDAR to drive positive change across industries.

The post Common Misconception About LiDAR appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The post Optimizing Aircraft Maintenance with LiDAR?Technology in Smart Airports appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>

Applications of LiDAR in Aircraft Maintenance

A. Detection of structural damage

One of the key applications of LiDAR in aircraft maintenance is the detection of structural damage. By scanning the surface of an aircraft with LiDAR sensors, technicians can identify any cracks or deformities that may compromise the integrity of the structure. This early detection allows for timely repairs to be made before more serious issues arise.

B. Monitoring corrosion and wear-and-tear

In addition to detecting structural damage, LiDAR can also be used to monitor corrosion and wear-and-tear on an aircraft’s exterior surfaces. Corrosion is a common problem in aviation due to exposure to harsh environmental conditions such as saltwater and extreme temperatures. By regularly scanning the surface of an aircraft with LiDAR sensors, maintenance crews can track changes in surface conditions over time and take proactive measures to prevent further deterioration.

C. Assessing engine performance

Furthermore, LiDAR technology can be utilized to assess engine performance by measuring parameters such as exhaust gas temperature and turbine blade vibration. This data provides valuable insights into the health of an aircraft’s engines and helps maintenance crews identify potential issues before they escalate into major malfunctions.

D. Enhancing predictive maintenance practices

By incorporating LiDAR into their maintenance practices, airlines can also enhance their predictive maintenance capabilities. Predictive maintenance involves using data analytics and sensor technologies to predict when equipment failures are likely to occur so that preventive actions can be taken proactively. With its ability to provide detailed 3D scans of an aircraft’s components, LiDAR enables airlines to gather precise data on equipment conditions and performance trends over time.

Advantages of implementing LiDAR technology in airports

A. Improved accuracy and efficiency in inspections: LiDAR technology provides highly accurate data on the condition of runways, taxiways, buildings, and other infrastructure within the airport. This allows airport authorities to quickly identify any issues such as cracks or potholes that may pose a safety risk. With this precise information at their disposal, maintenance teams can efficiently plan and execute repairs before they escalate into larger problems.

B. Cost savings through early detection of issues: By detecting potential issues early on, such as runway deterioration or obstruction on taxiways, airports can save significant costs in terms of repairs and operational disruptions. LiDAR technology enables proactive maintenance strategies that prevent costly emergency repairs and minimize downtime.

C. Enhanced safety for passengers and crew members: The accurate mapping capabilities of LiDAR technology help improve overall safety within the airport environment. By identifying potential hazards like debris on runways or obstacles near taxiways, airports can take immediate action to mitigate risks to passengers and crew members. Additionally, enhanced visibility provided by LiDAR sensors improves navigation for aircraft during takeoff and landing procedures.

D. Reduced downtime for aircraft: Efficient operations are crucial for minimizing delays in air travel. With LiDAR technology providing real-time data on runway conditions and airspace clearance, airports can optimize traffic flow while ensuring safe departures and arrivals. This results in reduced turnaround times for aircraft waiting to take off or land at the airport.

How Does LiDAR Improve Aircraft Maintenance?

A. Enhanced Inspection Capabilities

LiDAR technology allows maintenance crews to conduct detailed inspections of aircraft structures with precision and accuracy. By generating precise 3D models of an aircraft’s exterior, engineers can identify even minor damages or defects that may not be visible to the naked eye.

B. Predictive Maintenance

By using LiDAR data analytics, smart airports can predict potential maintenance issues before they occur. By analyzing historical data and monitoring changes in an aircraft’s structure over time, maintenance crews can proactively address issues before they escalate into costly repairs or downtime.

C. Increased Safety

Safety is paramount in aviation, and LiDAR technology plays a crucial role in ensuring safe operations at smart airports. By providing accurate measurements of runway conditions, obstacles, and other potential hazards, LiDAR helps pilots navigate safely during takeoff and landing.

D. Time Efficiency

Traditional methods of aircraft inspection can be time-consuming and labor-intensive. With LiDAR technology, maintenance crews can quickly scan an entire aircraft within minutes, reducing downtime and increasing operational efficiency.

Future Trends and Innovations in Aircraft Maintenance with LiDAR

A. Integration with AI and machine learning for advanced analytics

In the realm of aircraft maintenance, one of the future trends and innovations that is gaining traction is the integration of LiDAR technology with AI and machine learning for advanced analytics. This combination allows for more precise and efficient inspections, as well as predictive maintenance capabilities. By harnessing the power of data analysis, maintenance teams can better anticipate potential issues before they escalate, ultimately improving safety and reducing downtime.

B. Development of portable handheld devices for on-the-go inspections

Another exciting development in aircraft maintenance is the creation of portable handheld devices specifically designed for on-the-go inspections. These devices enable technicians to conduct thorough assessments quickly and efficiently, even in challenging environments. With real-time data at their fingertips, maintenance crews can make informed decisions promptly, enhancing overall operational efficiency.

C. Expansion into drone-based applications for hard-to-reach areas

Furthermore, there is a growing trend towards utilizing drone-based applications in aircraft maintenance for accessing hard-to-reach areas. Drones equipped with cameras and sensors can navigate confined spaces or high altitudes to perform detailed inspections without putting personnel at risk. This innovative approach not only enhances safety protocols but also increases the speed and accuracy of maintenance procedures.

Challenges and Considerations

A. Data security concerns

Despite these promising advancements, several challenges and considerations need to be addressed when implementing new technologies in aircraft maintenance. Data security concerns are paramount due to the sensitive nature of information collected during inspections. It is crucial to establish robust cybersecurity measures to safeguard against potential breaches or unauthorized access.

B. Training requirements for staff

Additionally, training requirements for staff must be taken into account when introducing new tools and technologies into existing workflows. Proper training ensures that technicians are proficient in operating equipment effectively while adhering to industry standards and regulations.

C. Initial investment costs

Moreover, initial investment costs associated with acquiring cutting-edge technologies may pose a barrier for some organizations looking to modernize their aircraft maintenance practices. However, it’s essential to weigh these upfront expenses against long-term benefits such as improved efficiency, reduced downtime, and enhanced safety measures.

Conclusion

As smart airports continue to evolve, the integration of advanced technologies like LiDAR is essential to optimize aircraft maintenance processes. By harnessing the power of this innovative technology, airports can ensure safer flights, reduce operational costs, and improve overall efficiency. The future looks promising as we witness the continued growth and adoption of LiDARs in transforming the aviation industry’s landscape, despite there are challenges inherent in adopting new trends and innovations in aircraft maintenance such as LiDAR integration with AI/ML or drone-based applications; by addressing concerns related to data security training requirements cost considerations.

The post Optimizing Aircraft Maintenance with LiDAR?Technology in Smart Airports appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The post Improving Efficiency and Safety in Ports with LiDAR-Based Automation Solutions appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>How LiDAR-Based Automation Solutions are Transforming Ports?

A. Enhancing Efficiency with LiDAR-Based Automation Solutions

One of the key advantages of using LiDAR-based automation solutions in ports is their ability to streamline operations and increase efficiency. By providing real-time data on vessel movements, container locations, and other critical information, LiDAR systems enable port operators to optimize their workflows and make informed decisions quickly.

1. Automated Container Handling

LiDAR sensors installed on cranes can accurately detect the position and orientation of containers on ships or storage yards. This information allows automated cranes to pick up containers more efficiently without human intervention, reducing loading/unloading times significantly.

2. Traffic Management

LiDAR sensors can be used to monitor vehicle traffic within the port area effectively. By analyzing real-time data from these sensors, port operators can identify congestion points or potential bottlenecks in advance and take corrective actions to ensure smooth traffic flow.

3. Inventory Management

With LiDAR technology’s precise mapping capabilities, port operators can maintain accurate inventory records by tracking container movements throughout the facility automatically. This helps prevent misplaced containers or delays in locating specific items when needed.

4. Automated Guided Vehicles (AGVs)

AGVs are self-guided vehicles that transport containers within ports without human intervention. By equipping AGVs with LiDAR sensors, these vehicles can navigate through busy port environments with precision and accuracy. LiDAR sensors provide real-time data on the vehicle’s surroundings, allowing it to avoid obstacles such as other vehicles or pedestrians.

5. Container Yard Management

LiDAR technology can be used to optimize container yard management by providing accurate information on container locations and movements. By installing LiDAR sensors throughout the yard, port operators can track containers in real time, improve inventory management, and reduce handling times.

6. Crane Automation

Cranes play a critical role in loading and unloading cargo ships at ports. By integrating LiDAR sensors into crane systems, operators can automate crane movements with high precision. LiDAR technology enables cranes to accurately position themselves over containers for efficient loading/unloading operations while ensuring safety by detecting any potential obstructions.

B. Ensuring Safety with LiDAR-Based Automation Solutions

In addition to improving efficiency, LiDAR-based automation solutions also play a crucial role in enhancing safety measures at ports. The advanced sensing capabilities offered by LiDAR systems help mitigate risks associated with human error or equipment malfunctions.

1. Collision Avoidance

LiDAR sensors installed on vehicles or equipment can detect obstacles in their path accurately and alert operators about potential collisions well before they occur. This proactive approach minimizes accidents involving personnel or machinery within the port premises.

2. Hazardous Environment Monitoring

Ports often handle hazardous materials that require special handling procedures to prevent accidents or environmental damage. LiDAR sensors equipped with gas detection capabilities can monitor air quality levels continuously and alert authorities if any toxic gases exceed safe limits.

3. Emergency Response Planning

In case of emergencies such as fires or chemical spills at ports, LiDAR-based automation solutions provide valuable assistance by quickly identifying affected areas through real-time mapping data. This information enables emergency responders to plan their actions more effectively while ensuring minimal impact on surrounding areas.

Benefits of Using LiDAR-Based Automation Solutions in Ports

1. Improved Efficiency: By automating various tasks such as container handling and crane operations, ports can significantly increase their operational efficiency while reducing turnaround times for ships.

2. Enhanced Safety: The use of LiDAR technology enhances safety by minimizing human error risks associated with manual operations while providing advanced collision avoidance capabilities.

3. Cost Savings: Automation solutions powered by LiDAR help reduce labor costs associated with manual tasks while optimizing resource utilization within ports.

4. Environmental Impact: Efficient port operations lead to reduced fuel consumption from idling vehicles/equipment resulting in lower carbon emissions which positively impacts environmental sustainability efforts.

5. Scalability: As global trade continues to grow rapidly, ports need scalable solutions that can adapt to increasing demands efficiently – making LiDAR-based automation an ideal choice due to its flexibility & adaptability features.

Future Outlook: Integration with AI for Smart Ports

As technology continues to evolve rapidly, there is immense potential for integrating AI (Artificial Intelligence) algorithms with LiDAR-based automation solutions. By leveraging AI-powered analytics tools, ports can gain deeper insights into operational patterns, predict maintenance requirements proactively, and optimize resource allocation based on demand forecasts. Furthermore, AI-driven decision-making processes enable ports to adapt quickly to changing market conditions while maintaining high standards of safety efficiency.

In conclusion, the adoption of LiDAR-based automation solutions has already begun transforming traditional port operations worldwide – leading toward smarter & more efficient supply chain networks. As advancements continue within this field including integration of AI/ML algorithms along with IoT technologies – we expect further optimization & streamlining across all aspects related to the maritime logistics industry. By embracing this cutting-edge technology, port authorities benefit from reduced costs, increased productivity, and enhanced overall performance. As we move towards an era of smart connected infrastructure, LiDAR is poised to play a pivotal role in shaping the future maritime industry landscape.

The post Improving Efficiency and Safety in Ports with LiDAR-Based Automation Solutions appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The post LiDAR?Anticollision Technology for Enhancing Safety in Construction appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>So how exactly does LiDAR anticollision technology work, and how can it benefit construction projects? Let’s delve into this innovative solution and explore its potential impact on enhancing safety in construction.

Understanding LiDAR Anticollision Technology

LiDAR anticollision technology utilizes sensors mounted on equipment such as cranes, excavators, or other heavy machinery to detect obstacles or potential collisions in real time. These sensors emit laser beams that bounce off objects within their range and calculate the distance between them. By continuously scanning the surroundings, LiDAR systems can create detailed 3D maps of the environment and identify any potential hazards.

When an obstacle is detected within a certain proximity to the equipment, the LiDAR system triggers an alert or automatically stops the machinery from moving further. This proactive approach helps prevent accidents caused by human error or blind spots that may not be visible to operators.

Here are some key ways in which LiDAR anticollision technology is transforming safety in construction:

1. Real-time Detection and Alerts: One of the primary benefits of LiDAR technology is its ability to provide real-time detection of objects within a certain range. By continuously scanning the environment around them, LiDAR sensors can detect obstacles or other machinery in proximity to a vehicle or equipment. In case of any potential collision risk, the system triggers an alert to warn operators immediately.

2. Improved Visibility: Construction sites are often cluttered with materials, debris, and blind spots that can obstruct visibility for operators. LiDAR sensors offer enhanced visibility by providing a 360-degree view of vehicles or equipment. This increased awareness helps operators navigate through tight spaces more effectively while avoiding potential hazards.

3. Collision Avoidance Systems: In addition to providing alerts to operators about nearby obstacles or vehicles, LiDAR anticollision systems can also take proactive measures to avoid collisions altogether. By integrating with automated braking systems or steering controls on machinery, LiDAR technology can help prevent accidents by automatically adjusting course or stopping when necessary.

4. Enhanced Worker Safety: Construction sites are dynamic environments where workers are constantly moving around heavy machinery and equipment. With LiDAR anticollision technology installed on vehicles like cranes or forklifts, workers can feel safer knowing that there is an extra layer of protection against potential accidents caused by human error or blind spots.

5. Cost Savings: While safety should always be the top priority in any industry – including construction – implementing advanced technologies like LiDAR anticollision systems also brings cost-saving benefits over time by reducing downtime due to accidents, insurance premiums, legal fees, etc.

6. Compliance with Regulations: As workplace safety regulations become increasingly stringent across industries, having advanced collision avoidance technologies like LiDAR will help companies stay compliant with these regulations.

Benefits of LiDAR Anticollision Technology

1. Enhanced Safety: The primary benefit of using LiDAR anticollision technology in construction is improved safety for workers on-site. By providing real-time alerts about potential hazards or collisions, this technology reduces the risk of accidents and injuries significantly.

2. Increased Efficiency: In addition to safety benefits, LiDAR systems can also improve efficiency on construction sites by minimizing downtime due to accidents or damage caused by collisions. By avoiding costly delays, projects can stay on schedule and within budget more effectively.

3. Accurate Monitoring: LiDAR sensors offer precise monitoring capabilities by creating detailed 3D maps of worksites. This data can be used for analysis purposes, such as tracking progress, identifying bottlenecks, or optimizing workflows for better project management.

4. Adaptability: LiDAR anticollision systems are versatile and can be integrated with various types of heavy machinery commonly used in construction projects. Whether it’s tower cranes at high-rise buildings or excavators at ground-level sites, these systems can adapt to different environments seamlessly.

5. Compliance with Regulations: As workplace safety regulations become stricter worldwide, incorporating advanced technologies like LiDAR into construction practices ensures compliance with industry standards while demonstrating a commitment to worker well-being.

Real-World Applications

LiDAR anticollision technology has already been successfully implemented across various construction projects globally:

1. High-Rise Buildings

Tower cranes equipped with LiDAR sensors help navigate complex urban environments safely while lifting heavy materials at great heights without risking collisions with nearby structures.

By using LiDAR sensors, tower cranes can navigate complex urban environments with precision and safety.

In addition to avoiding collisions with nearby structures, LiDAR-equipped tower cranes also help improve efficiency on construction sites. By providing real-time data on the position of materials and equipment, these sensors enable operators to make more informed decisions about how to safely maneuver heavy loads at great heights.

The integration of LiDAR technology into tower crane operations has revolutionized the way high-rise buildings are constructed. It has not only enhanced safety measures but also increased productivity and accuracy in lifting operations in dense urban areas.

2. Road Construction

Excavators fitted with anti-collision systems use LiDAR data mapping capabilities during roadworks projects ensuring safe operation near traffic lanes.

The LiDAR data mapping capabilities allow the excavator to create a detailed 3D map of its surroundings, helping it navigate through complex environments with precision.

By utilizing this technology, road construction companies can improve safety on job sites and minimize the risk of collisions with passing vehicles. This not only protects workers and equipment but also helps maintain traffic flow and reduce disruptions for commuters.

3. Tunneling Projects

Tunnel boring machines utilize LiDAR sensors for detecting obstacles underground preventing costly delays due to collision incidents.

LiDAR sensors are a key technology used in tunnel boring machines to detect obstacles underground. These sensors work by emitting laser pulses and measuring the time it takes for the light to bounce back, creating a detailed 3D map of the surrounding environment. This allows the tunnel boring machine operator to identify any potential obstacles such as rocks, pipes, or other structures that could pose a risk to the tunneling process.

By using LiDAR sensors, tunnel boring machines can navigate through complex underground environments with greater precision and efficiency. This helps prevent costly delays that can occur if the machine were to collide with an obstacle during excavation.

Future Outlook

As technological advancements continue at a rapid pace, we expect further innovations in LiDAR anticollison technology including integration with artificial intelligence (AI) algorithms enabling predictive maintenance scheduling based sensor data analysis.

The future looks promising as more companies recognize the value of investing in cutting-edge solutions like LiDAR anticollison technology not only improving worker safety but also boosting operational efficiency reducing costs associated with accidents.

In conclusion, LiDAR anticollision technology represents a significant step forward towards a safer and more efficient construction industry paving the way for a brighter future where workers return home safely each day knowing they have contributed something meaningful towards building a better world for us all.

By embracing this transformative tool, construction companies stand to gain a competitive edge while fostering a culture that prioritizes employee well-being above else ultimately leading to higher productivity and profitability in the long run.

With its proven track record of effectiveness and versatility across diverse applications, LiDAR anticollision technology is poised to revolutionize the way we approach safety management in the construction sector setting new standards of excellence for every project undertakes.

The post LiDAR?Anticollision Technology for Enhancing Safety in Construction appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The post The Fusion Of Infrared Thermal Imaging Technology And LiDAR Technology appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>

Understanding Infrared Thermal Imaging

Infrared thermal imaging is a technology that allows us to capture images based on heat radiation emitted by objects or living beings. This technology uses infrared sensors to detect heat signatures and convert them into visible images that show temperature variations. Infrared thermal imaging technology has been widely used in various industries for applications such as building inspections, electrical maintenance, medical diagnostics, surveillance, and more.

LiDAR Technology

LiDAR (Light Detection and Ranging) is a remote sensing method that uses light pulses to measure distances to objects or surfaces. This technology works by emitting laser beams toward a target area and measuring the time it takes for the light to bounce back. By analyzing these reflections, LiDAR systems can create detailed 3D maps of environments with high accuracy.

How to fuse infrared thermal imaging and LiDAR technology?

To fuse infrared thermal imaging technology and LiDAR technology effectively, it is essential to understand the principles behind each technology. Infrared thermal imaging captures the heat emitted by objects in the form of infrared radiation, allowing users to visualize temperature differences in a scene. On the other hand, LiDAR (Light Detection and Ranging) technology uses laser pulses to measure distances to objects and create detailed 3D maps of the environment.

One way to fuse these technologies is by overlaying thermal images onto LiDAR point clouds. This integration allows users to see both temperature information from infrared images and spatial data from LiDAR scans simultaneously. By aligning these two datasets accurately, analysts can identify hotspots or anomalies in a scene more efficiently.

Another approach is to use machine learning algorithms to process data from both technologies simultaneously. By training models on combined datasets, researchers can extract valuable insights that may not be apparent when analyzing each dataset separately. For example, combining thermal information with LiDAR data can help detect hidden objects or anomalies that are not visible in either dataset alone.

Furthermore, integrating real-time processing capabilities into infrared thermal imaging and LiDAR systems can enhance their usability for dynamic applications such as search-and-rescue missions or autonomous navigation. By fusing data streams from both technologies in real time, operators can make informed decisions quickly based on up-to-date information.

Fusing infrared thermal imaging technology and LiDAR technology offers numerous benefits for various industries and applications. By leveraging the strengths of both technologies through integration techniques like overlaying images or using machine learning algorithms, users can unlock new possibilities for data analysis and visualization. As advancements continue in sensor technology and software development, we can expect even more sophisticated fusion methods that push the boundaries of what is possible with these powerful tools combined.

The Power of Fusion: Combining Infrared Thermal Imaging with LiDAR

When infrared thermal imaging technology is fused with LiDAR technology, it creates a powerful synergy that enhances their capabilities. By combining these two technologies, users can benefit from:

1. Enhanced Data Accuracy: The fusion of infrared thermal imaging and LiDAR provides more comprehensive data sets by capturing both visual information (from infrared images) and spatial information (from LiDAR scans). This combination results in highly accurate representations of objects or environments.

2. Improved Object Detection: By integrating heat signatures from infrared thermal imaging with precise distance measurements from LiDAR scans, users can better detect objects even in challenging conditions such as low visibility or darkness.

3. Increased Efficiency: The fusion of these technologies streamlines data collection processes by capturing multiple types of information simultaneously. This efficiency leads to faster decision-making processes in various applications.

4. Expanded Applications: The combined use of infrared thermal imaging and LiDAR opens up new possibilities for applications across different industries including autonomous vehicle navigation systems where real-time detection capabilities are crucial for safe operation.

Applications Across Industries

Autonomous Vehicles

The fusion of infrared thermal imaging with LiDAR has significant implications for autonomous vehicles’ navigation systems.

– Enhanced object detection: Autonomous vehicles equipped with this fused technology can better detect obstacles on roads regardless of lighting conditions.

– Improved safety: Real-time data integration allows autonomous vehicles to make split-second decisions based on accurate environmental information.

– Increased reliability: The combination ensures redundancy in object detection systems leading to safer operations overall.

Agriculture

In the agriculture sector:

– Crop monitoring: Farmers can use fused data sets for precise crop monitoring including identifying areas affected by pests or diseases based on temperature differentials.

– Irrigation management: By analyzing both temperature variations (indicating moisture levels) along with topographical data from LiDAR scans farmers optimize irrigation schedules leading to increased crop yields.

Construction

For the construction industry:

– Site planning: Fused data sets provide detailed insights into terrain characteristics allowing construction companies to plan projects efficiently while minimizing risks associated with uneven terrains.

– Structural inspections: Combining thermographic imagery showing heat loss/gain patterns along structural elements helps identify potential weaknesses before they become critical issues.

Future Outlook

As technological advancements continue at a rapid pace, the fusion between infrared thermal imaging and LiDAR holds immense potential for transforming various industries and opening up new possibilities for innovative applications.

By leveraging this powerful combination, organizations stand poised to gain competitive advantages through enhanced accuracy, efficiency, and expanded capabilities across diverse sectors.

Conclusion

The fusion between infrared thermal imaging and LiDAR represents a significant step forward in remote sensing technology with far-reaching implications across multiple industries. By harnessing the power of these advanced technologies, users can unlock new opportunities for improved data accuracy and object detection efficiency and increase applications across various fields. The future is bright for this synergistic fusion as it continues to push boundaries and drive innovation in ways that were previously unimaginable.

The post The Fusion Of Infrared Thermal Imaging Technology And LiDAR Technology appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The post LiDAR-Powered Rail Transit Systems for Better Urban Development appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The Benefits of LiDAR-Powered Rail Transit Systems

1. Improved Infrastructure Planning and Design

LiDAR?technology provides accurate data on existing infrastructure, topography, and land use patterns. This information can help city planners make informed decisions about where to build new rail lines, stations, and other transit facilities. By creating precise 3D models of the urban environment, developers can optimize route designs to minimize disruptions and maximize efficiency. LiDAR?data can be used for detailed mapping of urban areas where rail transit systems are being developed or expanded. This information helps city planners make informed decisions about infrastructure development projects such as station locations, track alignments, land use planning around stations, etc.

2. Enhanced Safety

One of the key benefits of using LiDAR in rail transit systems is improved safety. By providing accurate real-time data about track conditions, obstacles on or near the tracks, and potential hazards, LiDAR helps prevent accidents and ensures passenger safety.

Rail transit systems powered by LiDAR offer enhanced safety features compared to traditional transportation modes. LiDAR sensors can detect obstacles in real-time, such as vehicles or pedestrians on tracks, allowing trains to automatically adjust their speed or stop if necessary. This reduces the risk of accidents and improves overall passenger safety.

3. Increased Efficiency

LiDAR technology enables rail transit systems to operate more efficiently by optimizing train schedules based on real-time data analysis. By monitoring passenger flow patterns and adjusting service frequencies accordingly, operators can reduce wait times for commuters while maximizing capacity utilization. This leads to more efficient operations, reduced delays, and improved overall service quality.

4. Environmental Sustainability

One of the key advantages of LiDAR-powered rail transit systems is their environmental sustainability. By reducing reliance on fossil fuels through electrification or hybrid propulsion systems, these trains produce lower emissions than traditional diesel-powered vehicles. Additionally, by promoting public transportation over private cars, cities can reduce traffic congestion and air pollution levels.

Case Study: The Impact of LiDAR-Powered Rail Transit Systems in Customer S

Customer S has been at the forefront of adopting cutting-edge technologies in its urban development projects including its rail transit system. LiDAR-powered rail transit systems have significantly enhanced the efficiency and safety standards across its rail transit network.

By integrating LiDAR sensors into their trains’ onboard systems along with fixed installations along track sides at critical points like curves or intersections; the rail transit system operators have been able to monitor track conditions continuously in real-time which has led not only increased operational efficiency but also reduced maintenance costs due early detection potential issues before they escalate into major problems affecting service reliability passengers’ safety alike.

Furthermore; the data collected from these sensors also provides valuable insights into passenger flow patterns within stations enabling better crowd management during peak hours ensuring smoother boarding and alighting processes thus enhancing the overall commuter experience while traveling through the bustling metropolis efficiently and comfortably without any hiccups along way!

Future Opportunities with LiDAR-Powered Rail Transit Systems

As cities continue to grow rapidly around the world, there are numerous opportunities for leveraging LiDAR-powered rail transit systems in urban development projects:

1. Smart City Integration: Integrating LiDAR data with other smart city technologies such as Internet-of-Things (IoT) devices can create seamless connectivity between different modes of transport within a city’s infrastructure network.

2. Mixed-Use Development: Rail stations powered by LiDAR technology present opportunities for mixed-use developments that combine residential spaces with commercial areas like shopping malls or office buildings.

3. Last-Mile Connectivity: Incorporating micro-mobility solutions such as e-scooters or bike-sharing services at rail stations equipped with LiDAR sensors could enhance last-mile connectivity options for commuters.

4. Disaster Response Planning: In disaster-prone regions prone regions like earthquake zones or flood-prone areas; using LiDAR-equipped trains could provide critical support during emergency response operations due to their ability to map affected areas quickly post-disaster events occur.

In conclusion, LiDAR-powered rail transit systems are transforming how we think about urban development projects worldwide – offering improved planning accuracy; increased safety measures; greater operational efficiencies; and environmental sustainability benefits among others which will shape future smart cities across the globe!

Future Prospects: Integrating AI with LiDAR-Powered Rail Transit Systems

The prospects for LiDAR-powered rail transit systems look promising with advancements in Artificial Intelligence (AI) integration capabilities coming into play soon! AI algorithms can analyze vast amounts of LiDAR-generated spatial temporal datasets identifying patterns and trends that the human eye might miss out on otherwise leading smarter decision-making processes when it comes to optimizing operations and managing emergencies effectively well!

For example; AI algorithms could predict potential faults and failures based on historical sensor readings allowing maintenance crews to proactively address issues before they occur minimizing downtime disruptions when services are provided to passengers alike! Additionally; AI-driven predictive analytics could help optimize train schedules and routes based on current demand patterns and weather forecasts ensuring maximum efficiency utilization of resources available while minimizing environmental impact associated with running public transport networks in densely populated cities worldwide!

In conclusion, the LiDAR-powered rail transit system represents a game-changer realm of urban mobility offering a plethora of benefits ranging from enhanced safety operational efficiency environmental sustainability infrastructure planning among others making them the ideal choice for modern cities looking towards sustainable future growth prosperity! With continued investments in research developments in this field, we can expect to see even more exciting innovations emerge transforming the way people commute, live, and work within our increasingly interconnected world today and tomorrow beyond!?

The post LiDAR-Powered Rail Transit Systems for Better Urban Development appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

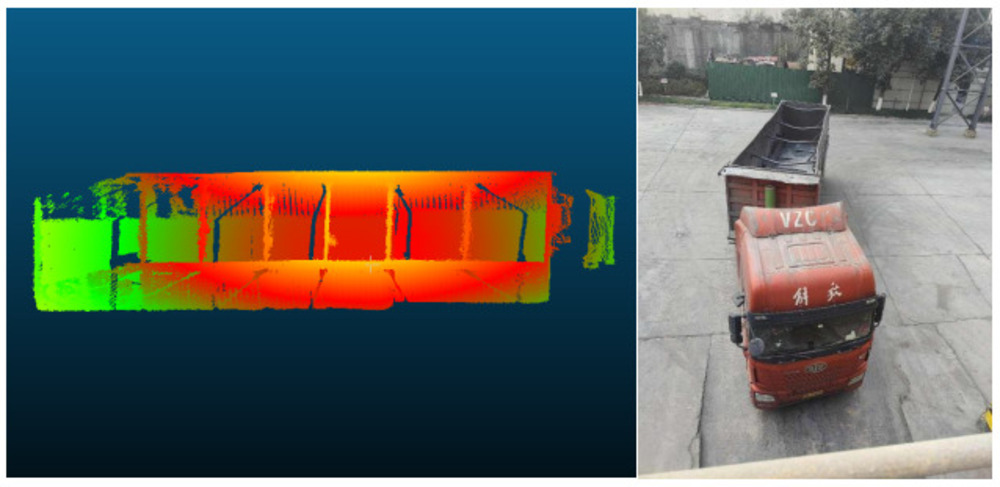

]]>The post Utilizing LiDAR for Measuring Bulk Trucks’ Load Capacity: Maximizing Profits through Enhanced Precision appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>The Need for Precision in Measuring Load Capacity

Accurately measuring the load capacity of bulk trucks is essential for several reasons. Firstly, overloading a truck can lead to safety hazards on the road, as well as potential fines for violating weight restrictions. On the other hand, underloading a truck means missed opportunities to maximize profits by carrying more goods in one trip. Therefore, finding the optimal balance between maximizing load capacity without exceeding legal limits is crucial for any logistics company.

Traditionally, measuring load capacity has been done using manual methods such as weighing scales or visual estimation. These methods are not only time-consuming but also prone to human error. Inaccurate measurements can lead to costly mistakes that impact both safety and profitability.

Introducing LiDAR Technology

LiDAR technology offers a revolutionary solution to the challenges posed by traditional measurement methods. By using laser beams to create high-resolution 3D maps of an object or environment, LiDAR provides precise measurements with an accuracy of up to millimeters.

When applied to measuring bulk trucks’ load capacity, LiDAR scanners can be mounted at strategic points on loading docks or conveyor belts where trucks are being loaded. As goods are loaded onto the truck bed, the LiDAR sensors capture real-time data on volume and weight distribution.

Benefits of Using LiDAR for Measuring Load Capacity

When it comes to measuring bulk trucks’ load capacity, traditional methods such as manual weighing or volume calculations can be time-consuming and prone to errors. LiDAR technology offers several advantages in this context:

1. Accuracy: LiDAR technology provides highly accurate measurements that eliminate human error from manual methods. LiDAR sensors can capture precise measurements of the truck’s cargo volume and weight distribution.

2. Efficiency: Real-time data capture allows for quick adjustments during loading processes without causing delays. The speed at which LiDAR systems can collect data makes them ideal for real-time monitoring of loading operations.

3. Safety: By ensuring that trucks are not overloaded or underloaded, companies can reduce risks associated with accidents on the road. By reducing the need for manual intervention during loading processes, LiDAR helps improve safety on worksites.

4. Cost-effectiveness: Maximizing load capacity means fewer trips needed to transport goods, leading to cost savings on fuel and labor.

Implementation Challenges?

While LiDAR technology offers significant benefits in measuring bulk trucks’ load capacity accurately; there are some challenges associated with its implementation:

1. Initial investment: Acquiring and installing LiDAR systems may require upfront investment costs that some companies may find prohibitive.

2. Integration with existing systems: Integrating LiDAR data into existing data management systems or software platforms may require additional resources and expertise.

3. Training requirements: Employees need training on how to operate and interpret data from LiDAR systems effectively.

Despite these challenges, many companies have already started reaping the benefits of using LiDAR and enhancing their operational efficiency while maximizing profits through optimized truckload capacities.

Technical Research Forecasting

Looking ahead, technical research in this field is expected to focus on enhancing the capabilities of LiDAR systems for measuring bulk trucks’ load capacity:

1. Improved data processing Algorithms: Researchers are working on developing advanced algorithms that can analyze complex 3D data captured by LiDAR sensors more efficiently.

2. Integration with IoT devices: The integration of LiDAR systems with Internet-of-Things (IoT) devices will enable seamless data sharing across different platforms.

3. Enhanced automation features: Future developments may include autonomous loading systems that leverage AI algorithms to optimize cargo placement within trucks.

By staying abreast of these technological advancements, companies operating in the mining, construction, logistics and other industries reliant on bulk transportation stand poised to maximize their profits through enhanced precision using LiDAR for measuring bulk trucks’ load capacity.

Case Study: ABC Cement Plant

A Cement Plant recently implemented a pilot program utilizing Neuvition LiDAR + PTZ to measure their bulk trucks’ load capacity accurately at their plant. By integrating real-time data from LiDAR into their existing data management system; ABC Cement Plant can optimize their loading processes significantly.

The results were impressive:

1- Reduced instances of overloading/underloading

2- Increased overall truckload capacities

3- Decreased fuel consumption due to fewer trips required

Overall, ABC Cement Plant saw a noticeable improvement in both operational efficiency & profitability after implementing LiDAR technology.

Conclusion

In conclusion, leveraging advanced technologies like LiDAR presents exciting opportunities for industries looking to enhance precision & maximize profits through optimized bulk trucks’ load capacity. By investing in innovative solutions like LiDAR, companies can stay ahead of the competition while delivering superior service levels to customers.

LiDAR technology has immense potential for revolutionizing the way we measure bulk trucks’ load capacity. By leveraging this cutting-edge technology effectively, companies cannot only enhance their operational efficiency but also gain a competitive edge in today’s dynamic business environment. With ongoing advancements in LiDAR systems and software solutions, only time will tell how far we can go in maximizing profits through enhanced precision using LiDAR for measuring bulk trucks’ load capacity. Whether you’re looking to improve your company’s bottom line or increase operational efficiencies; LiDAR could be the game-changing solution you’ve been searching for.

The post Utilizing LiDAR for Measuring Bulk Trucks’ Load Capacity: Maximizing Profits through Enhanced Precision appeared first on Neuvition | solid-state lidar,lidar sensor suppliers, lidar technology, lidar sensor.

]]>